Industry 4.0

Smart Factory Solution

Descriptions

Refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data. Industry 4.0, which encompasses IIoT and smart manufacturing, marries physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better connected ecosystem for companies that focus on manufacturing and supply chain management. While every company and organization operating today is different, they all face a common challenge—the need for connectedness and access to real-time insights across processes, partners, products, and people.

Process

Plant OEE,Analytics, Moblity & CMS Sol.

Overall equipment effectiveness (OEE) software tracks and analyzes equipment performance data obtained via equipment sensors or manual input. The tool is used for measuring equipment productivity by unit, shift, facility, etc., and provides valuable insights on how to improve equipment effectiveness and the production process and reduce production losses.

Virtualization system

Segmenting a single physical machine into multiple virtual machines enables you to make the most of available hardware, lower costs, and improve efficiency. Without virtualization, untold server capacity goes to waste. Not only does this cost businesses money, but it also contributes to the global carbon footprint. The six benefits highlighted here are only the tip of virtualization’s iceberg of potential. If you are not already putting virtualization to work, it is time to critically examine your infrastructure. You may be surprised by how much it can benefit from virtualization.

IIOT compliance solutions, Predictive

The Industrial Internet of Things (IIoT) refers to the extension and use of the Internet of Things (IoT) in industrial sectors and applications. It brings together machines and processes to monitor, collect, exchange, and analyze real-time sensor data to deliver meaningful insights. IoT-based predictive utilizes historical data from multiple sources including IoT devices and sensors to make accurate predictions about asset health, utilization, and the possibility of failure, enabling you to take action based on this information.

End to End Intergration (wired & wireless)

Wireless and wired networks have commonly evolved separately. However with the integration of quad-play services (i.e., mobile/fixed voice, video, and data) into a single network infrastructure the provisioning of end-to-end connections spanning both the wireless and the wired domains becomes an important issue. In this paper two solutions are proposed for implementing an integrated end-to-end signaling for establishing QoS-guaranteed connections in integrated WiMAX and MPLS based networks. The two solutions are based on the integration of WiMAX management messages and RSVP-TE signaling. Their main difference consists in the way flow WiMAX message and RSVPTE signaling are triggered and coordinated.

Smart panel monitoring accessories .

In smart MCC, all motor feeders are configured with the required configurations like maximum current, maximum voltage, trips, faults, alarms, etc. All the feeders are configured with a unique slave address (ID) and placed in one or more networks. The real-time motor parameters will be monitored in stand-alone SCADA system or the same data can be transferred to control room PLC or DCS systems.

Robotic solution -- Universal

Robot Solutions allows industrial robots to perform specific manufacturing tasks. This can lower costs, improve product quality, and decrease production time. Robot Solutions has teamed up with robotics manufacturer, Yaskawa Motoman Robotics, Fanuc,ABB Robotics and Kuka Robotics,to give customers more integration options. As an official Solution Provider, Robot Solutions offers support and a broader selection of robots. We offer a turn-key solutions on your Robot Challanges.

AGVs, SMART materials handling system

Automated guided vehicles are being used in various end-use industries, such as logistics, automotive, healthcare, manufacturing, food & beverages, and others. Increased productivity and reduced labor costs are the key factors driving the need for industrial equipment. The demand for AGVs is expected to grow owing to the increasing automation in industries. Increasing industrialization has led to the continuous need for customized material handling and transport solutions for fueled efficiency. For instance, in November 2021, JBT, a technology solutions provider in the food and beverage industry, acquired Urtasun Technologia Alimentaria, a provider of vegetable and fruit processing solutions. This acquisition aims to scale JBT’s business globally by providing automated solutions in the food industry and letting Urtasun Technologia Alimentaria expand its product offerings.

Application of AGVs, SMART materials handling system

AGVs find applications across towing, forklift trucks, light load carriers, unit load careers, pallet trucks, and assembly lines. Their hybrid segment is equipped with forks and becoming popular. Some of their other end users include military & defense, aerospace, automotives, foods & beverages, healthcare, and retail. These vehicles can easily replace monotonous labor jobs. Eventually, they may reduce the costs and enhance the workflow.

AGVs are used in the medical sector to facilitate efficient transportation of medical equipment, surgical case carts, & patient meals. They are used to clean rooms in hazardous environments. These vehicles are also adopted by the automotives industry.

Maintenance, Quality, Production

Maintenance, Quality, Production

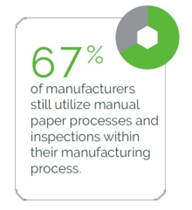

Between verifying product quality at the time of manufacturing before shipment and ongoing aftermarket maintenance and service, inspections ensure products continue to perform as intended. The importance of inspections cannot be overstated and yet for many original equipment manufacturers (OEMs), many inspection processes are still manual, involving paper-based processes and requiring a highly trained eye.

2D digital or paper-based instructions on how to perform inspections are often ambiguous, quickly outdated, and cumbersome to flip through while trying to execute the inspection at hand. Likewise, paper-based records on the results of inspections involve tedious data entry and difficult-to-navigate storage and retrieval. These processes prove to be incapable of democratizing knowledge widely to support continuous improvement.

Inspection for Quality and Field Maintenance Use Cases with Augmented Reality

Throughout a product’s lifetime, inspection is a constant.

When it comes to quality inspections and field service maintenance inspections, the limitations of manual and paper-based processes contribute to costly rework and scrap, customer dissatisfaction, and issues with employee safety, training, and retention.

To address these challenges head-on, OEMs are leveraging augmented reality (AR) for the most complex inspection use cases––and reaping meaningful business benefits.

MANUFACTURING QUALITY INSPECTIONS

As a critical aspect of the quality control process, manufacturing quality inspections occur before the sale and shipment of products and are instrumental in finding errors and defects before products reach customers. Pre-assembly inspections focus on the raw materials and components process but the product can also be inspected during and postproduction to ensure it meets engineering specifications.

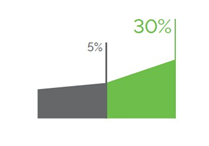

According to Quality Digest, experts have estimated that the Cost of Poor Quality (CoPQ) can range from 5% to 30% of gross sales for manufacturing and service companies.

FAQ

Frequently Ask Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Magna nec felis a ex vehicula potenti tellus rhoncus consectetur nisi. Consectetuer nascetur a blandit facilisis scelerisque.

Magna nec felis a ex vehicula potenti tellus rhoncus consectetur nisi. Consectetuer nascetur a blandit facilisis scelerisque.

Magna nec felis a ex vehicula potenti tellus rhoncus consectetur nisi. Consectetuer nascetur a blandit facilisis scelerisque.

Magna nec felis a ex vehicula potenti tellus rhoncus consectetur nisi. Consectetuer nascetur a blandit facilisis scelerisque.

Magna nec felis a ex vehicula potenti tellus rhoncus consectetur nisi. Consectetuer nascetur a blandit facilisis scelerisque.