Industrial IOT

process manufacturing

Suninfomation Soloution can help Plants to enhance OEE , reliablity , energy efficiency , productivity & safety while reducing emission & maitennce cost . Through IIOT maschine and equipment can connect to logistics system and work in progress componenet can be managed directly . They can even manufacturing ecosystem for the proces industry.

Advantage –

- Increase Equipment Efficiency .

- Improve Capacity.

- Increased Productivity .

- Enviorment Monitoring .

- Energy Savings

Discrete manufacturing

The Plants of the future incorporate varying degrees of Collaboration between human & robots. Artificail – driven maschine will take over the process that workers consider repeatitive and monotounas . The sensors & shopfloor controller can also improve the factory performance maangment standerds. The aquired data to be forwadred to desboard , which are used as performance infdicator . These indicators enables deceision making to clearly understand the over all productivity of their production areas.

Advantage –

- Indstrial Digitalization .

- Enhansed visual Management

- Cost saving of the manpower.

- Effective output.

MASCHINE HELATH MANAGEMENT

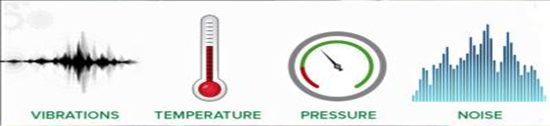

Manufacturing is a complex sector that requires human workers to oversee all aspects of manufacturing processes. Traditionally, checking and maintaining the health of machines or maintenance in manufacturing relies heavily on manual processes. However, with the growing dearth of workers, the industry is forced to embrace connected, smart solutions to meet the demands and boost productivity at the desired quality. The advent of the industrial internet of things (IIoT) and Industry 4.0 is already unleashing the huge value in industrial settings around the world. Today, manufacturers are increasingly leveraging IIoT-driven machine condition monitoring to resolve equipment issues and maintain machine health.

Condition monitoring typically enables product quality control by identifying equipment health, including engine temperature, cutting speed, spindle vibration frequency, and ambient parameters, such as temperature and humidity. In other words, condition monitoring is essentially monitoring parameters that define the health of a machine or asset.

Advantage –

- Comprihensive service .

- AI & Deep learning

- Improved precission & efficiency .