IOT Sensors, Actuator & Gateways

The Internet of Things (IoT) consists of several technological layers which all play a role in the route from simply connecting ‘things’ and devices to building applications that serve a clear goal, whether it’s for consumer applications, enterprise IoT, connected communities such as smart cities, specific use cases in vertical industries or Industrial IoT projects as we know them from Industry 4.0.

IoT technology should really be IoT technologies as there are several of course and the ones that matter depend on the goal. However, they fit in this IoT technology stack that has various layers, starting with IoT devices, and myriad technologies per layer.

- The first is the IoT device level, as without accurate sensors, actuators and IoT devices in general, no accurate data and without accurate data no Internet of Things, let alone IoT projects or products/services.

- The second is the IoT gateway, which we covered more in-depth but deserves a spot as a layer and certainly in an overview of the IoT device layer with which it is strongly connected and for which is a necessary level towards the next steps of actionable data and business applications or consumer apps and services.

- The third is the IoT platform layer where we connect with the business and consumer applications and services, as well as the development of these services and the management and interconnection with the first two layers.

IoT bridges the gap between the physical world and the digital world and that starts with things.

Solutions offering

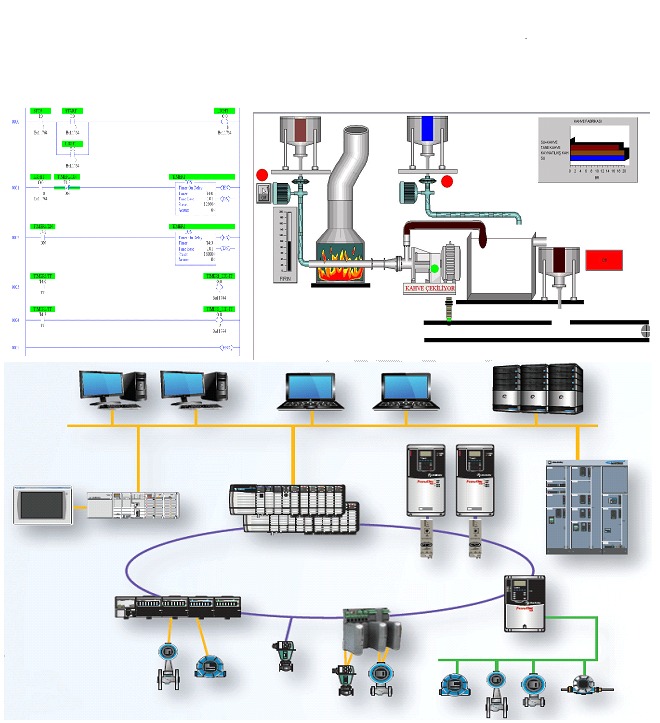

Instrumentation & Automation

Measuring and controlling process variables are a meticulous business. Perfecting those abilities within a production, laboratory or manufacturing arena is a fine art, one that requires specialized instrumentation and automation (I&A) products and services.

Relevant excels in specialized I&A control for a wide range of conditions, including, but not limited to, temperature, pressure, level and flow, precision custody transfer, process automation, remote communication and full-scale DCS solutions. In the most critical of times, Relevant’s platform and our diverse product line out performs.

Pressure

Pressure measurement can be accomplished with many different types of instruments such as: pressure sensors, pressure transducers, pressure transmitters, pressure switches, pressure gauges and all types of compatible pressure accessories. In the proper selection of pressure instrumentation, consider the following: metallurgy and material compatibility with the process, pressure rating, signal type (4-20mA), pressure range and how you will connect the instrument to the process.

Level

Level measurement is an ever-growing space. Technology helps give you reliable and accurate measurement for your most challenging applications. These technologies include head pressure, differential pressure, bubbler, floats, displacers, rotary paddle, vibration forks, capacitiance, ultrasonic, load cell, magnetorestirictive, ultra sonic, radar and inductive.

Flow

The measurement of flow is in the top five most common measurements taken industry wide. To serve our customer’s needs effectively, an offering of all flow technologies must be accessible. These flow technologies include electromagnetic, variable area, vortex, Coriolis, ultrasonic transit time, calorimetric, differential pressure, open channel, paddle wheel & turbine.

Temperature

If you are looking to monitor or control temperature, have difficult process conditions to overcome, or you are looking for the right Temp.Sensor for your needs, We offers different types of temperature indication for every simple or complex need including sensors, transducers, transmitters, switches, gauges, RTDs, thermo wells and thermocouples.

Analytical & Analytics

Analytical instruments, sensors and systems measure critical process parameters such as pH/ORP and conductivity in a wide variety of applications for reliable process monitoring and control. Suninfomation offers a comprehensive portfolio of analytical instruments and sensors to ensure production operates smoothly, efficiently and safely, allowing users to optimize costs.

Happy Client

Wind Farms

Solar Farm