Prescriptive Maintenance

Mauris eget lobortis consectetur nibh ex quam mus cras

Prescriptive Maintenance

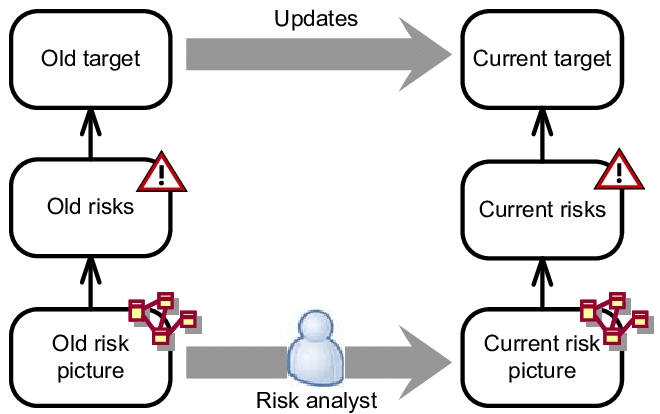

Prescriptive Maintenance generations, maintenance professionals have used preventive maintenance to avoid equipment failures and turned to reactive maintenance when their assets did fail. With the emergence of the Industrial Internet of Things (IIoT), maintenance professionals can now connect tools, software, and sensors to collect, store, and analyze multiple data sources in one place.

Those tools are already unlocking predictive maintenance, where sensors and software predict future failures. However, many maintenance leaders are looking toward a future based on a concept called prescriptive maintenance, where machine learning and artificial intelligence not only predict failures but also identify solutions.

The benefits of Prescriptive Maintenance

- Develop predictive maintenance models for maximizing asset life, operational performance, or uptime

- Leverage historical data and real-time data

- Optimize maintenance operations

- Minimize downtime and increase efficiency

Predictive maintenance shares many similarities with prescriptive maintenance. Predictive maintenance uses data-driven, proactive maintenance methods — such as condition-based maintenance (CBM) — to analyze equipment health and help predict when maintenance should be performed.